About the Company

Gazprom neftekhim Salavat is Russia’s major petrochemical complex situated in the Republic of Bashkortostan in the town of Salavat.

A company set up in 1948 as Industrial Complex No. 18 in 10 years turned into a rapidly developing center of petrochemistry and oil refining.

In Soviet times, the Company organized production of low density polyethylene (LDPE), styrene, butyl and fatty alcohols, ammonia and urea, ethylene and propylene, polystyrene, glycol etc.

By the end of the 1990s, Salavatnefteorgsintez set a course for the increase of production capacities: ethylbenzene, styrene and polystyrene facilities were constructed. Nowadays, bitumen, high density polyethylene (HDPE), urea granulation, visbreaking and vacuum distillation (AVT-6) production units, the latter with the capacity of 6 mta, have been put into operation.

In 2011, the Company was integrated into the Gazprom system. 99.9% of Gazprom neftekhim Salavat shares belong to Gazprom Pererabotka.

Major activities

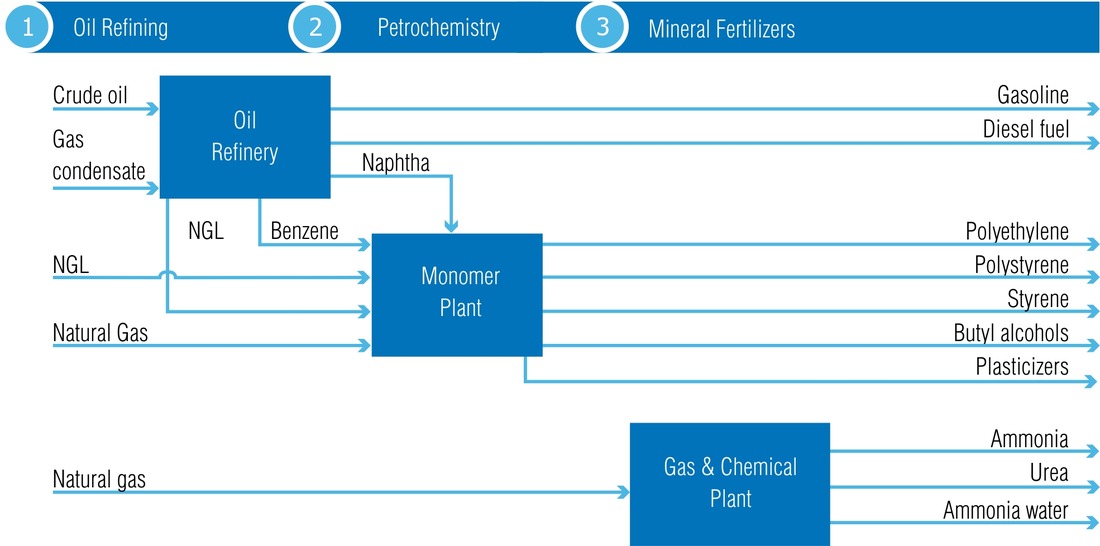

Gazprom neftekhim Salavat is one of the leading companies of Gazprom Group in oil refining, petrochemistry and mineral fertilizers production.

Gazprom neftekhim Salavat comprises the Oil Refinery, Gas & Chemical Plant and Monomer Plant.

The Company carries out a full cycle of crude hydrocarbons processing and produces more than 150 different products, including 70 main products: motor gasolines, diesel fuel, oil fuel, fuel oil (mazut), road bitumen, road bitumen feedstock, sulphur, low-density polyethylene, slurry high-density polyethylene, ethylene, styrene, GPPS PSM-E, butyl alcohols, urea, ammonia to name a few. The rate of declared and certified products is about 50 %.

The Company takes one of the leading positions in the domestic production of a range of products including butyl alcohols and plasticizers, styrene and styrene copolymers.

The products of the company are shipped to consumers located in all federal subjects of Russia. Export supplies of oil products are mainly directed to CIS countries, North Africa and Turkey. Petro- and gas chemicals are exported to over 20 CIS and non-CIS countries and the largest volumes are shipped to Turkey and CIS countries.

Environmental policy

Gazprom neftekhim Salavat operates based on such principles as minimization of energy-output and materials-output ratios along with highest possible labour capacity. The Company ensures dynamic and sustainable development and places high emphasis on programs in energy saving, resource saving and environmental protection. It acquires and establishes new, mostly innovative, technologies in the mentioned spheres, following the example of Gazprom parent company.

The implemented projects of the investment program focus on application of higher and safer technologies, reduction of environmental impact and environmental compliance. All modern plants of the Company meet high requirements in terms of industrial and environmental safety.

Social policy

The Company is actively involved in realization of social projects. The employees are provided with a full package of social guarantees.

Medical services are provided by Medservis, an advanced clinic.

The Company has constructed up-to-date sports facilities for sports activities, such as the Salavat Sports and Concert Complex with an ice rink and a swimming pool, the Neftekhimik Sports Palace, and reconstructed the stadium and the town park.

Creative teams of the Neftekhimik Palace of Culture take part and win in the corporate Fakel Festival.

The Company maintains a youth policy. It has continuously been developing a talent pool for its own production purposes, beginning from school age. Sputnik Children’s Recreation Camp is the Russian leader in the arrangement of children’s recreation.

The Veterans organization unites 9.5 thousand pensioners of the Company. The primary trade union comprises over 4500 members.

Prospects

To date, the Company has made its policy to implement a large-scale investment program. It aims at construction of new and revamp of the existing production facilities based on modern and environmentally friendly technologies.

Current construction facilities

- Catalytic Cracking Complex

- Sulphuric and Alkaline Waste Treatment Unit

- renovation of waste treatment facilities

Enlarged photo (JPG, 858 KB)